Why do we need a surface finish?

Surface finish is necessary for 2 key reasons:

- To prevent oxidation of exposed copper surfaces which would lead to poor solderability/reliability.

- To provide a reliable, solderable surface which acts as the connection between the PCB and the components.

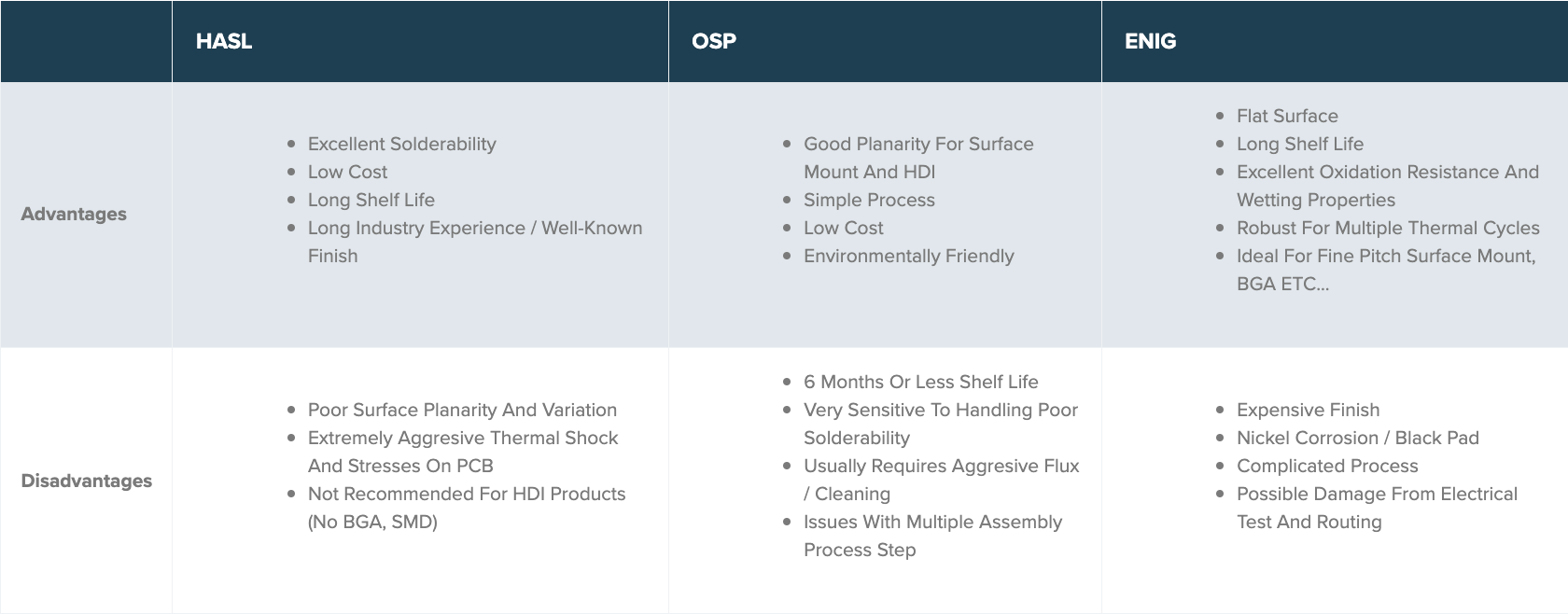

Advantages and disadvantages

| HASL | OSP | ENIG | |

|---|---|---|---|

| Advantages |

|

|

|

| Disadvantages |

|

|

|

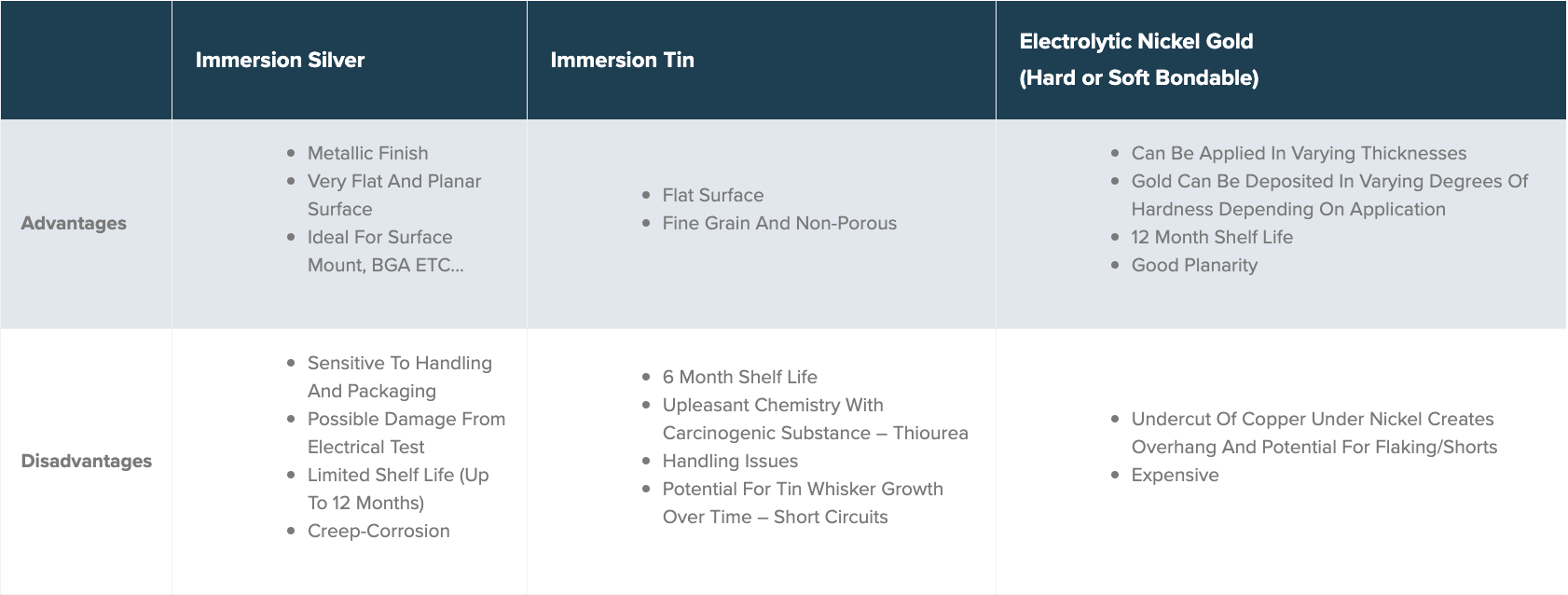

Advantages and disadvantages

| Immersion Silver | Immersion Tin | Electrolytic Nickel Gold (Hard or Soft Bondable) |

|

|---|---|---|---|

| Advantages |

|

|

|

| Disadvantages |

|

|

|

Advantages and disadvantages

Advantages and disadvantages