Via hole filling/plugging of a PCB is a process where the via hole is filled with solder mask or resin.

Via holes that are filled/plugged improve the PCB reliability by decreasing the possibility of trapped air/liquid in the via, thus ensuring good yield through assembly.

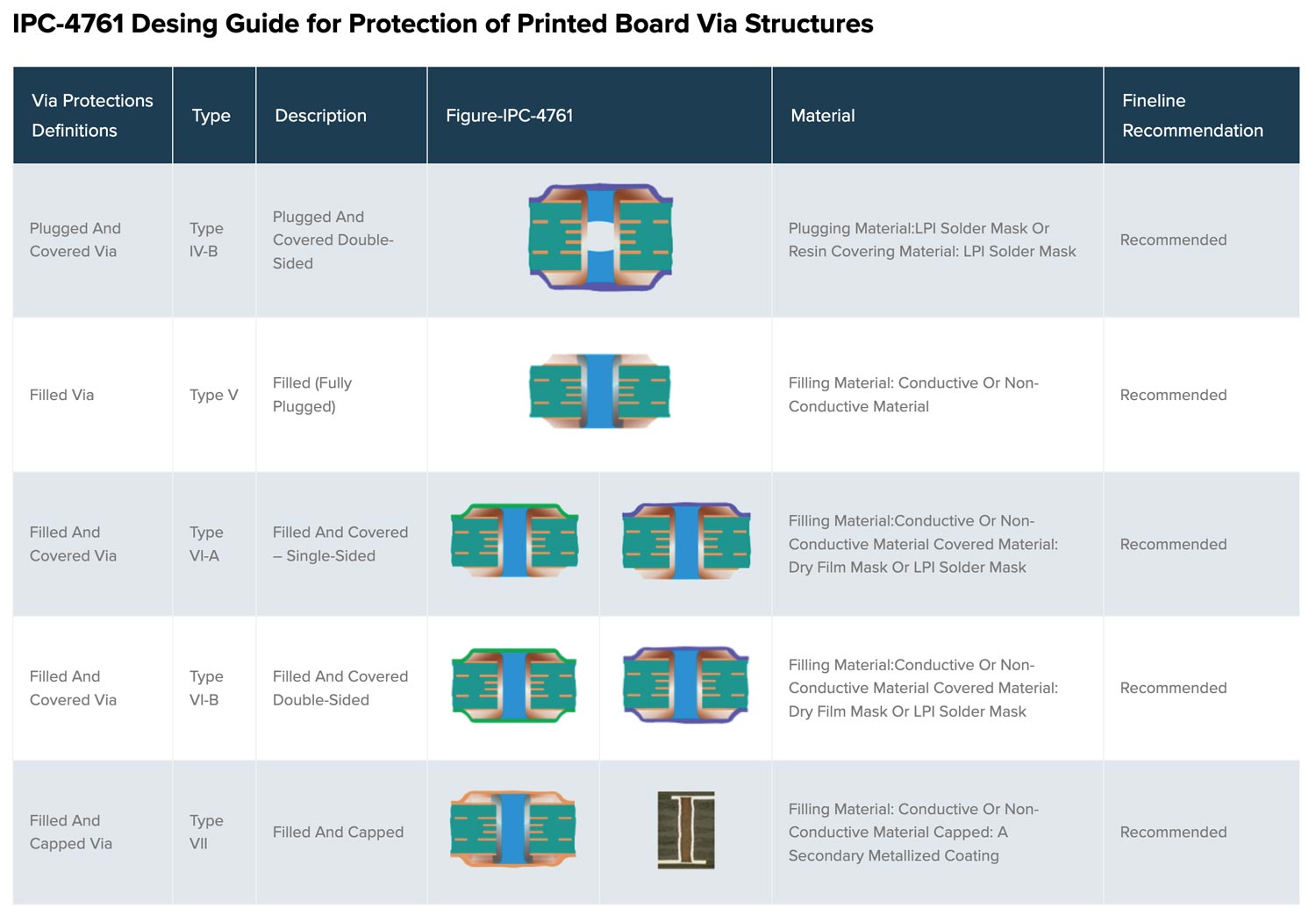

See the table below – Fineline’ s recommendation for via protection according to IPC-4761 via types.

For more information please contact Fineline.

IPC-4761 Design Guide for Protection of Printed Board Via Structures

| Via Protections Definitions | Type | Description | Figure-IPC-4761 | Material | Fineline Recommendation | |

|---|---|---|---|---|---|---|

| Plugged and Covered Via | Type IV-b | Plugged and Covered Double-sided |  |

Plugging material:LPI solder mask or Resin Cover material: LPI solder mask |

Recommended | |

| Filled Via | Type V | Filled (fully plugged) |  |

Filling material: Conductive or non-conductive material | Recommended | |

| Filled and Covered Via | Type VI-a | Filled and Covered – Single-Sided |  |

|

Filling material:Conductive or non-conductive material Cover material: Dry film mask or LPI solder mask |

Recommended |

| Filled and Covered Via | Type VI-b | Filled and Covered Double-sided |  |

|

Filling material:Conductive or non-conductive material Cover material: Dry film mask or LPI solder mask |

Recommended |

| Filled and Capped Via | Type VII | Filled and Capped |  |

|

Filling material: Conductive or non-conductive material Capped: a secondary metallized coating |

Recommended |

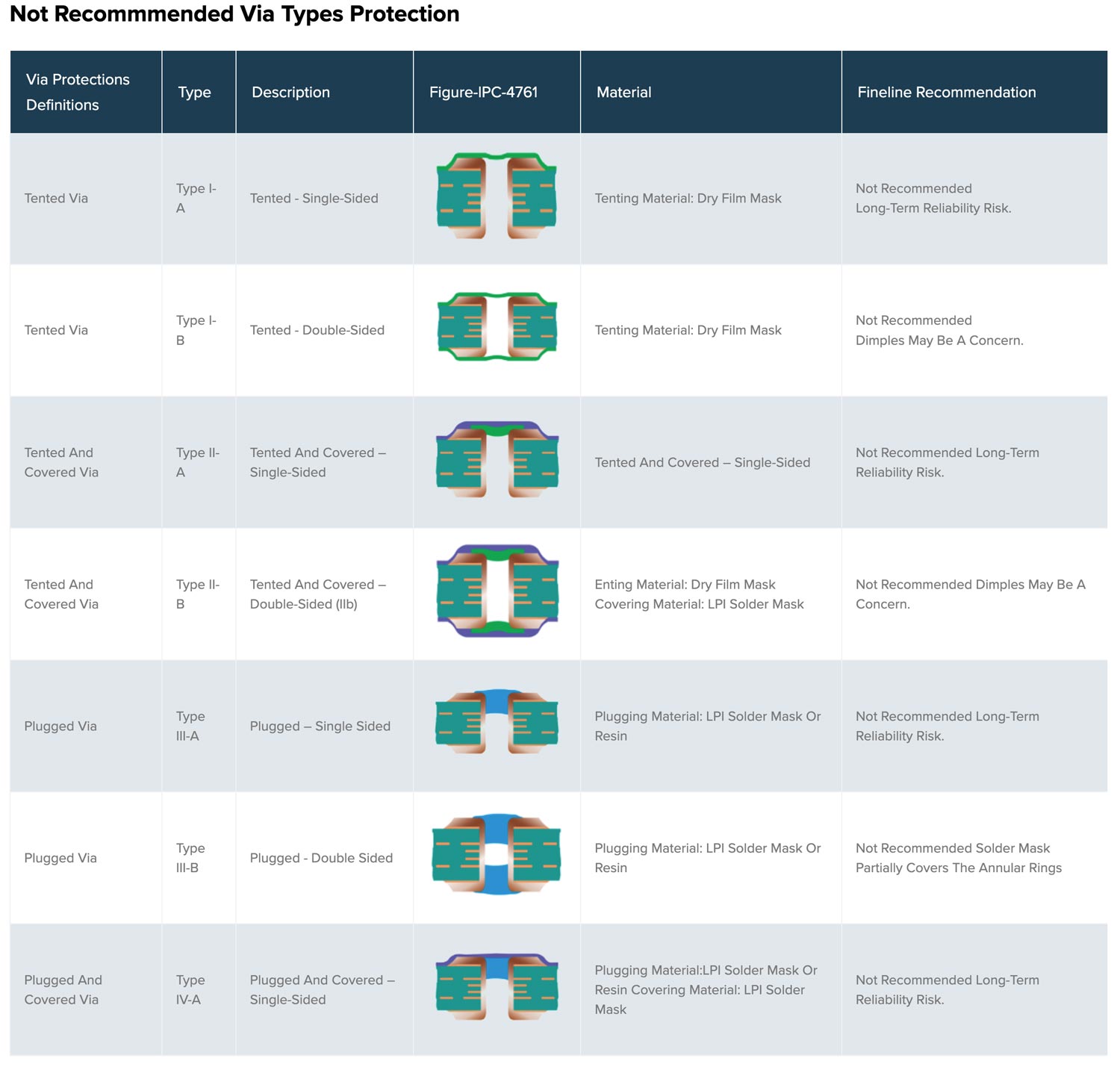

Non-Recommended Via Protection Types

| Via Protections Definitions | Type | Description | Figure-IPC-4761 | Material | Fineline Recommendation | |

|---|---|---|---|---|---|---|

| Tented Via | Type I-a | Tented - Single-Sided |  |

Tenting material: Dry film mask | Not Recommended Long-term reliability risk. |

|

| Tented Via | Type I-b | Tented - Double-Sided |  |

Tenting material: Dry film mask | Not Recommended Dimples may be a concern. |

|

| Tented and Covered Via | Type II-a | Tented and Covered – Single-Sided |  |

Tented and Covered – Single-Sided | Not Recommended Long-term reliability risk. | |

| Tented and Covered Via | Type II-b | Tented and Covered – Double-Sided (IIb) |  |

Tenting material: Dry film mask Covering material: LPI Solder mask |

Not Recommended Dimples may be a concern. | |

| Plugged Via | Type III-a | Plugged – Single Sided |  |

Plugging material: LPI solder mask or Resin | Not Recommended Long-term reliability risk. | |

| Plugged Via | Type III-b | Plugged - Double Sided |  |

Plugging material: LPI solder mask or Resin | Not Recommended Solder mask partially covers the annular rings | |

| Plugged and Covered Via | Type IV-a | Plugged and Covered – Single-Sided |  |

Plugging material:LPI solder mask or Resin Cover material: LPI solder mask |

Not Recommended Long-term reliability risk. | |